هیدرولیک و پنوماتیک (ویکرز)

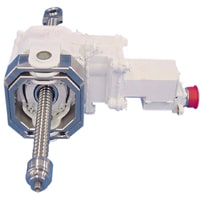

2 position actuator

Eaton’s electric motor-operated valve actuators are designed to operate valves requiring 90 degrees of rotary movement from fully open to fully closed positions. Actuators are available in 28 VDC single and dual motors and in multiple form factors. The motor drives a worm and wheel and/or an epicyclic gearbox. For dual motor designs, a differential ensures that if one motor fails, the other will continue operating the valve. Travel limits are controlled by micro switches, Hall effect sensors or potentiometer. Actuator provides visual and electrical indication and can be assembled with other Eaton valves using an adapter.

4 position actuator

Eaton’s four-position valve actuator provides a full 360 degrees of rotary motion, with actuator position commanded by four power input pins in the electrical connector. A control logic board determines the shortest rotational distance from its current position and features over-voltage protection and position hold with loss of power and resume when power returns. Additional features can be added. Travel limits are controlled by four micro switches or hall effect sensors. The actuator provides visual and electrical indication and can be assembled with other Eaton valves using an adapter.

Airframe ball valves

With a well-established record of proven performance, Eaton ball valves are designed for both fluid (fuel and PAO) and pneumatic submerged-in-tank and dry-bay applications. For submerged applications, remote and pedestal configurations are available to maximize installation flexibility. Valve assemblies incorporate a spherical plug with journals mounted in bearings, allowing plug rotation to open and close the flow path. An input shaft connected to the spherical plug incorporates an interface for Eaton’s actuator. Lightning strike protection can be provided, and port configurations include two-port and multiport options.

Ball valve

Eaton’s Carter ball valve (Model 64015) is designed to mate with our underwing refueling nozzles to ease strainer inspections and add a true swivel action to the combination unit

Brake system components

Eaton’s brake control valves enhance landing gear system performance and reliability and include brake metering valves, brake shuttle valves and emergency/parking brake valves. The metering valve receives brake inputs from aircraft rudder pedals to direct metered pressure from the hydraulic system to the brake actuators, with metered pressure determining the amount of braking force. Brake master cylinders also are available for braking systems that are independent from main hydraulic systems. Part numbers: Brake metering valve – 72420 Master brake cylinder – 11699 Emergency brake valve – 70012-30 Brake shuttle valve – 70599

Butterfly valve

Eaton butterfly valves for fluid (fuel and PAO) and pneumatic systems are excellent cost- and weight-saving solutions for high flowrate applications and offer a well-established record of proven performance on commercial and military aircraft. The valve disc incorporates journals mounted in bearings, allowing the disc to be rotated 90 degrees to open and close the flow path. Valves can be combined with most Eaton actuators.

Cabin pressure relief and isolation valves

Eaton’s cabin pressure relief and isolation valves are integral safety components of pneumatic pressurized airlock systems on space structures. Designed to accommodate manned and unmanned missions, our valves can support both manual and motor driven space systems. Our highly reliable cabin pressure relief and isolation valves help ensure the safety of crew, cargo, habitat and mission, and contribute to long term survivability and success of space exploration initiatives. These compact, lightweight valves have completed multiple space missions on varied platforms and in diverse environments, as a result Eaton can provide pedigree with reduced lead times, qualification cycles and cost.

Check / non-return valves

Eaton’s check/non-return valves can attain ultra-low pressure drops — a feature that helps conserve energy while reducing lifecycle operational costs. Our valves are used on major commercial and military platforms.

Air-to-air rail launchers

Eaton’s air-to-air rail launchers provide a weapon interface with operational flexibility and weight savings for the latest multirole fighter aircraft. Our advanced missile launcher (AML) enables carriage on wing-tip or pylon stations and is compatible with multiple fighter jet platforms. Our NATO multi missile launcher (NMML) is for the carriage and release of long- and short-range missiles without the need for role change. It features a digital interface, and in-flight operable lock for increased safety and can accommodate a countermeasure dispenser.

Air-to-ground ejector racks

Eaton is a leader in the design, prototyping, certification and manufacturing of pyrotechnic and pneumatic air-to-ground ejector racks. Pyrotechnic air-to-ground ejector racks The advanced technology in our pyrotechnic carriage and release products eliminates high operational and support costs while increasing safety, reliability and consistency for ejecting stores from combat aircraft. Our pyrotechnic Air-to-ground ejector racks employ release units to provide pneumatic or pyrotechnic ejection for a wide range of munitions and can be installed in aircraft bomb bays, wings or fuselage pylons. Pneumatic air-to-ground ejector racks Our pneumatic bomb ejection rack (PBER) is a pneumatic replacement with the same form, fit and function as the dual piston pyrotechnic ejection system MAU-12. It utilizes pneumatic ejector technology which requires significantly less logistical support, maintenance and repair than legacy systems resulting in lower total cost of ownership. Our fully pneumatic PBER is capable of carrying and releasing stores of up to 2,882 lb. (1,307 kg) and is the only one on the market designed with the flexibility to carry larger adjacent stores.

Air-to-ground rail launchers

Eaton’s air-to-ground rail launchers enable fighter jets, attack helicopters and unmanned aerial vehicles to safely carry and release air-to-ground missiles. We offer single and twin carriage rail launcher systems that are optimized for the suspension and release of air-to-ground stores from lighter platforms such as unmanned aircraft and helicopters or jets with a smaller payload configuration requirement. Our triple carriage rail launcher system enables multiple weapons to be carried simultaneously for critical operations like close air support for ground troops.

Chaff and flare dispenser

Eaton’s chaff and flare dispenser system is comprised of flare dispensers, which provide off-board infrared seeking missile countermeasure capability, and chaff dispensers that deploy particles to neutralize threats from radar guided missiles. Our chaff and flare dispensers are qualified to the latest nuclear hardening and vibration standards and are designed to meet individual customer requirements.

Control actuation system manifold

Eaton’s control actuation system (CAS) manifold assembly is a cold gas, pneumatic fin actuation control subsystem that manages the movement of canard fins on laser guided weapons enabling the weapon to adjust position inflight and track to target. Our CAS manifold assembly consists of an accumulator, regulator and solenoid valve, which are integrated into the manifold, and features a high-pressure nitrogen cold gas storage system activated by pyrotechnic initiators. The Eaton CAS manifold features a simplified assembly configuration making it a high potential energy solution in a compact package. We also offer complete on-site development and testing.

Controller

Eaton’s specialized aerospace controllers for military and commercial customers are designed for a variety of system applications, including hydraulic, fuel gauging, fuel inerting, secondary flight controls and nose wheel steering control systems, as well as hydraulic and electrical actuation systems. We also support all phases of aircraft certification and are well-versed in industry standard processes such as RTCA DO-178, DO-254, DO-160 and ARP-4754. In addition, Eaton is qualified to address specific design considerations that must be accounted for in aircraft systems, such as intrinsic safety 25.981 compliance, power management/distribution, and reliability and maintainability.

Electromechanical actuator

Eaton’s electromechanical actuators employ the latest technologies for motors, gear trains and controls, with innovative designs that deliver higher power densities. Actuators are available in standard voltages as well as 270 VDC, which requires a brushless design and motor controller.

Pneumatic compressor systems

Eaton’s pneumatic compressor systems provide on-aircraft pneumatic pressurization capability with integrated motor control and moisture removal and include high pressure gas generation and dual phase cooling applications. Our compressor systems are qualified to the strictest military environmental standards and can be used on fixed- and rotary-wing aircraft as well as combat and tactical ground vehicles. Eaton pneumatic compressor systems are used in our pneumatically actuated carriage and release systems , electronics cooling and personal microclimate cooling systems. With our broad system capabilities encompassing compressor technology, motor and drive technology, electronic controls, solenoids, and valves, Eaton offers a comprehensive solution for your gas generation needs.

Pneumatic ejection valves

Eaton’s pneumatic ejection valves provide the energy to rapidly unlock weapon release linkages and extend ejector pistons of weapon release systems on military bomb racks and carriages. Our valves feature cold gas deployment using nitrogen or compressed air and can integrate with cold gas stored in attached pressure vessels or supplied from onboard compressors. Regardless of the cold gas storage system used, our valves reliably control the flow of gas enabling safe weapon separation from the aircraft. Our pneumatic ejection valves offer highly repeatable, clean ejection capability and their low maintenance requirements can result in lower lifecycle costs.

Pneumatic wing and tail actuators

Eaton’s pneumatic wing and tail actuators provide up to 15,000 psi of pneumatic pressure to deploy the wings and tail fin of missiles to their full open flight position in one tenth of a second increasing the stability and range of stand-off, smart weapons. Eaton can customize a pneumatic system to meet the requirements of your application’s specific envelope, force and actuation rate and can be configured in either single stage or dual stage. Our wing and tail actuators can compensate for temperature and offer hydraulic, pneumatic or mechanical dampening

Self-contained actuation and dampers

Eaton’s advanced valve and actuation technologies include self-contained actuators and damper assemblies that can be combined to provide complete actuation systems for a variety of applications.