Pressure Transmitters and Transducers

Rosemount™ 3051 Coplanar™ Pressure Transmitter

The industry-proven Rosemount 3051 with patented Coplanar technology allows for direct mounting in multiple measurement applications. 10-year stability and 150:1 rangedown produce reliable measurements and wide application flexibility. Available with a graphical, back-lit display, Bluetooth® connectivity, Flow and Level specific configuration and enhanced software capabilities designed to access the data you need faster than ever before.

Specifications

WarrantyUp to 5-year limited warranty

RangedownUp to 150:1

Communication Protocol4-20 MA HART®, WirelessHART®, FOUNDATION™ fieldbus, PROFIBUS® PA, 1-5 V Low Power HART®

Measurement RangeUp to 2000 psi (137,89 bar) differential

Up to 2000 psig (137,89 bar) gage

Up to 4000 psia (275,79 bar) absolute

Process Wetted Material316L SST, Alloy C-276, Alloy 400, Tantalum, Gold-plated 316L SST, Gold-plated Alloy 400

DiagnosticsBasic Diagnostics, Process Alerts, Loop Integrity Diagnostics, Plugged Impulse Line Diagnostics

Certifications/ApprovalsSIL 2/3 certified to IEC 61508 by an independent 3rd party, NSF, NACE®, hazardous location, see full specs for complete list of certifications

Wireless Update Rate1 sec. to 60 min., user selectable

Power Module LifeUp to 10-year life, field replaceable (order separately)

Wireless RangeInternal antenna (225 m)

Rosemount™ 3051S MultiVariable™ Transmitter

The Rosemount 3051S MultiVariable Transmitter is a best-in-class solution customized to obtain measurement combinations of differential pressure, static pressure and process temperature. This multivariable transmitter is a cost-effective device that reduces pipe penetrations, impulse piping and connection systems. This device is also engineered with built-in flow calculations for fully compensated mass flow measurements.

Specifications

WarrantyUp to 15-year limited warranty

RangedownUp to 200:1

Communication Protocol4-20 mA HART™, WirelessHART®, FOUNDATION™ Fieldbus

Measurement RangeUp to 2000 psi (138 bar) differential, Up to 6092 psi (420 bar) static

Process Wetted Material316L SST, Alloy C-276, Tantalum, Gold-plated 316L SST

DiagnosticsBasic Diagnostics

Certifications/ApprovalsNSF, NACE™, hazardous location, see full specs for complete list of certifications

Differential Pressure Flow

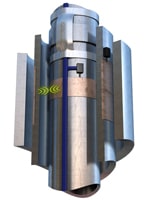

Rosemount™ 3051SFA Annubar™ Flow Meter

The Rosemount 3051SFA Annubar Flow Meter is a no-equal solution with a patented, averaging pitot tube that delivers superior measurement accuracy over a wide flow range. This flow meter can measure multiple variables and is engineered with an integrated thermowell for temperature measurement. Its patented T-shaped sensor is capable of obtaining measurements via a single pipe penetration while maintaining a small profile in the pipe to reduce permanent pressure loss and increase energy savings.

Specifications

WarrantyUp to 15-year limited warranty

RangedownUp to 200:1 (14:1 flow turndown)

Measurement RangeUp to 1000 inH2O (2,48 bar) differential, Up to 3626 psia (250,00 bar) absolute, Up to 3626 psig (250,00 bar) gage

Line Size2 to 96 in. (50 to 2440 mm)

OutputDifferential pressure, static pressure, process temperature, scaled variable, mass flow, volumetric flow, energy flow

Communication Protocol4-20 mA HART®, WirelessHART®, FOUNDATION™ Fieldbus

Process Wetted Material316 SST, Alloy C-276

DiagnosticsBasic Diagnostics, Loop Integrity, Process Intelligence, Plugged Impulse Line

Certifications/ApprovalsSIL 2/3 certified to IEC 61508 by an independent 3rd party, NACE, hazardous location, see full specs for complete list of certifications

Rosemount™ 2051 Differential Pressure Flow Transmitter

Designed to provide industry-standard performance, the Rosemount 2051 Differential Pressure Flow Transmitter offers dependable differential pressure (DP) flow measurements. For easy installation, this DP flow transmitter can be pre-assembled to various primary elements. This safety-certified transmitter also features a local operator interface (LOI) with easy-to-use menus and built-in configuration buttons for device commissioning without tools.

Specifications

WarrantyUp to 5-year limited warranty

RangedownUp To 100:1

Measurement RangeUp to 2000 psi (137,9 bar) differential

OutputDifferential pressure, scaled variable

Communication Protocol4-20 mA HART®, WirelessHART®, FOUNDATION™ Fieldbus, PROFIBUS®, 1-5 V Low Power HART®

Process Wetted Material316L SST, Alloy C-276, Tantalum

DiagnosticsBasic Diagnostics

Certifications/ApprovalsSIL 2/3 certified to IEC 61508 by an independent 3rd party, NSF, NACE®, hazardous location, see full specs for complete list of certifications

Downhole Applications

Roxar™ Downhole Network Controller (DHNC)

Roxar Downhole Network Controller provides unrivalled insight and control over production operations. The industry–leading equipment gives operators everything they need to establish an Intelligent Downhole Network (IDN), which can accommodate up to 32 sensors on a single cable. The highly accurate pressure and temperature information captured is invaluable in simultaneously managing a range of wells or separate zones, and gives operators better production control.

Specifications

Maximum number of instrumentsRS422, 10 Mbit Ethernet, RS485 (optional)

Cable requirement1 TEC (mono or dual conductor)

Maximum cable length16,000 m (52,400 ft)

Main InterfacesRS422, 10Mbit Ethernet

Main ProtocolsMODBUS RTU, TCP

Roxar™ Downhole Wireless Systems

Roxar Downhole Wireless Systems continuously monitor annulus B temperature and pressure for the subsea well’s lifetime. Comprised of a wireless reader and a wireless PT Transponder, the advanced system improves production and offshore safety, providing early high–pressures warnings, protecting casing integrity and preventing pressure build–up.

Specifications

Pressure range14.5 – 20,000 psi (1 – 1,400 bar)

Temperature Range-5 – 205°C (23 – 400°F)

Pressure accuracy±0.345 bar (5 psi)

Temperature accuracy±0.5°C (0.9°F)

Measurement typeQuartz crystal

ElectronicsSilicon-On-Insulator (SOI) technology

Maximum sampling rate1 per second

Material of wetted partsInconel 718

Casing sizes12-1/4″ and 10-3/4″

Tubing sizes7″ and 5-1/2″

Nuclear Pressure Instrumentation

Rosemount™ 3155N Nuclear Qualified Pressure Transmitter

Offering accurate differential and gage analog pressure measurements for nuclear applications, the Rosemount 3155N Nuclear Qualified Pressure Transmitter is engineered for reliable performance over an extended service life. This is an industry-standard solution qualified per IEEE Std 323™-1974/1983/2003 and this device withstands radiation exposure of 167 Mrads TID gamma and seismic levels to 8.5g ZPA. This resilient transmitter is also engineered for high steam temperature performance up to 437 °F (225 °C).

Specifications

Output Signal4-20 mA

RangedownUp To 10:1

Measurement RangeUp to 2000 psi (13.79 MPa) Differential, Up to 4000 psig (27.58 MPa) Gage

Housing MaterialSST

Process Wetted Material316L SST

Seismic Rating8.5g ZPA Seismic

Radiation Rating165 Mrad (1.65 kGy) TID Gamma Radiation

Steam/Pressure Temperature437°F (225°C) Steam/Temperature

Qualification StandardIEEE Std 323™-1974/1983/2003

IEEE Std 344™ – 1975/1987/2004

Product LiteratureThe Product Data Sheets and Manuals posted on this web-site are intended for general product information only, with errata included. They may not represent the latest revision or contain information relating to recent product notifications, if any.

Contact InformationPlease contact Rosemount Nuclear Instruments, Inc. at 1-952-949-5200 or RNII.info@emerson.com for the most current information available

Rosemount™ 3152N Nuclear Qualified Pressure Transmitter

Engineered for precision, the Rosemount 3152N Nuclear Qualified Pressure Transmitter can provide reliable analog pressure measurements in nuclear applications over an extended service life. This transmitter is qualified per IEEE Std 323™-1974/1983/2003 and IEEE Std 344™-1975/1987/2004 to meet industry standards. This device also features stringent quality control during the manufacturing process, which includes traceability of pressure-retaining parts, special nuclear cleaning and hydrostatic testing.

Specifications

Output Signal4-20 mA

RangedownUp To 10:1 (5:1 for Range 1)

Measurement RangeUp to 2000psi (13.79 MPa) Differential, Up to 4000psig (27.58 MPa) Gage, Up to 4000psia (27.58 MPa) Absolute

Housing MaterialSST, Aluminum

Process Wetted Material316L SST, Alloy C-276

Seismic Rating8.5g ZPA

Radiation Rating6.5 Mrad (65 kGy) TID Gamma Radiation

Steam/Pressure Temperature290°F (143.3°C ) Steam/Temperature

Qualification StandardIEEE Std 323™-1974/1983/2003

IEEE Std 344™-1975/1987/2004

Product LiteratureThe Product Data Sheets and Manuals posted on this web-site are intended for general product information only, with errata included. They may not represent the latest revision or contain information relating to recent product notifications, if any.

Contact InformationPlease contact Rosemount Nuclear Instruments, Inc. at 1-952-949-5200 or RNII.info@emerson.com for the most current information available

Differential Pressure Level

Rosemount™ 1199 Diaphragm Seal System

The Rosemount 1199 Diaphragm Seal System offers protection to transmitters, guarding against hot and cold, corrosive or erosive processes. This seal system features a variety of solutions, including industry-specific seals for difficult processes. This safety certified system does not require mounting hardware and can be used for many pressure measurement applications, providing reliable, remote measurements.

Specifications

Seal System TypeDirect Mount, Remote Mount, Tuned-System, Balanced System

Transmitter ConnectionWelded-Repairable, All Welded

Process ConnectionFlanged: ANSI/ASME, EN/DIN, GOST, & JIS

Threaded: NPT, DIN, ISO

Hygienic

Process Wetted Material316L SST, Alloy C-276, Alloy 400, Tantalum, Gold-plated Alloy 400, Gold-plated 316L SST, CorrosionShield PFA coated 316 SST, see PDS for full list of materials

Certifications/ApprovalsSIL 2/3 certified to IEC 61508 by an independent 3rd party, 3A, NACE®, hazardous location, see PDS for full list of certifications

Rosemount™ 3051L Level Transmitter

Direct mount or use a Tuned-System™ assembly that optimizes performance and reduces temperature effects by 10-20% for improved response time by over 80% versus traditional installations. Built-in diagnostics detect electrical loop issues and alert you to corrosion, water in the housing, or unstable power supply. Available with a graphical, back-lit display, Bluetooth® connectivity, Level specific configuration and enhanced software capabilities designed to access the data you need faster than ever before.

Specifications

WarrantyUp to 5-year limited warranty

Max. Operating PressureUp to 300 psi (20,68 bar)

Process Temperature RangeBased on fill fluid:

Maximum 401°F (205°C), Minimum -157°F (-105°C)

Communication Protocol4-20 MA HART®, WirelessHART®, FOUNDATION™ fieldbus, PROFIBUS® PA, 1-5 V Low Power HART®

Seal System TypeDirect Mount, Tuned-System

Transmitter ConnectionWelded-Repairable

Process ConnectionFlanged: ANSI/ASME, EN/DIN, JIS

Process Wetted Material316L SST, Alloy C-276, Tantalum

DiagnosticsBasic Diagnostics, Process Alerts, Loop Integrity Diagnostics, Plugged Impulse Line Diagnostics

Certifications/ApprovalsSIL 2/3 certified to IEC 61508 by an independent 3rd party, NACE®, hazardous location, see full specs for complete list of certifications

Wireless Update Rate1 sec. to 60 min., user selectable

Power Module LifeUp to 10-year life, field replaceable (order separately)

Wireless RangeInternal antenna (225 m)

Instrument Manifolds

Rosemount™ R305 Integral Manifold

The Rosemount R305 Integral Manifold assembles directly to the patented Rosemount Coplanar™ transmitter, eliminating the need for a flange. The Pressure-Lock™ Valve, exclusively featured on the Rosemount R305 and R306 manifolds, offers simplified operation, enhanced reliability and increased operator safety. This lightweight premium manifold is available in 2-, 3- and 5-valve configurations which allows for instrument isolation and controlled venting to ensure measurement integrity.

Specifications

Max. Operating Pressure6250 psi (431 bar)

Max. Operating Temperature750°F (399°C)

Manifold Material316 SST/316L SST

Packing MaterialPTFE, Graphite-based

Process Connection1/2″ -14 NPT female

Orientation: Parallel with transmitter, 90° to transmitter

Certifications/ApprovalsCleaning for special services, sour gas (meets NACE MR 0175/ISO 15156, MR0103), see full specs for complete list of certifications

WarrantyUp to 5-year limited warranty

Rosemount™ R306 In-Line Manifold

The Rosemount R306 In-Line Manifold assembles directly to in-line gauge or absolute pressure transmitters. Exclusively featured on the Rosemount R306 and R305 manifolds, the Pressure-Lock™ Valve offers simplified operation, enhanced reliability and increased operator safety. The R306 manifold is available with a 2-valve configuration for instrument isolation and drain/vent capabilities.

Specifications

Max. Operating Pressure10000 psi (689 bar)

Max. Operating Temperature750°F (399°C)

Manifold Material316 SST/316L SST

Packing MaterialPTFE, Graphite-based

Process Connection1/2″ -14 NPT female

Orientation: Parallel with transmitter

Certifications/ApprovalsCleaning for special services, sour gas (meets NACE MR 0175/ISO 15156, MR0103), see full specs for complete list of certifications

WarrantyUp to 5-year limited warranty

Pressure Accessories

Rosemount™ 333 HART® Tri-Loop™ Signal Converter

With the Rosemount 333 HART Tri-Loop Signal Converter, you can easily obtain up to three additional analog outputs. This signal converter is designed to convert a digital HART multivariable signal into three independent 4-20 mA analog process variables without additional transmitters and wiring. Available as a high-alarm or low-alarm device, this product also offers DIN rail mount options and electrically isolated analog output channels for flexible configurations.

Specifications

Output Signal3 additional analog signals

Ambient Temperature Effect±0.15% of span

Stability±0.1% of span for 12 months

Rosemount™ 751 Field Signal Indicator

Gain access to important process data with the Rosemount 751 Field Signal Indicator, a device designed for harsh industrial environments. This field signal indicator operates well with any 2-wire transmitter that measures input variables such as pressure, flow, liquid level or temperature. Ideal for installations where an integral meter would be difficult to view, this device is also corrosion resistant and offers both explosion-proof and intrinsic safety certifications.

Specifications

Materials of ConstructionEnclosure: Low-copper aluminum; Paint: Polyurethane; O-rings: Buna N; Meter mounting materials: GE polyphenylene oxide plastic

Enclosure RatingNEMA Type 4x. CSA Type 4x. IP66

Certifications/ApprovalsHazardous location, marine type,�see full specs for complete list of certifications

Pressure Gauges

Rosemount™ Wireless Pressure Gauge

The Rosemount Wireless Pressure Gauge features a robust design with industry-proven sensor technology to resist common traditional gauge failures. This pressure sensor provides up to 10 years of maintenance-free operation and replaces mechanical components for more reliable readings and a higher overpressure limit. This innovative device also features WirelessHART®technology that delivers reliable field data communications as frequently as once per minute.

Specifications

Measurement RangeUp to 4,000 psi (275.8 bar) Gage, Up to 10,000 psi (689.5 bar) Absolute

Display/Interface4.5 in. (114 mm)

Housing MaterialEngineered polymer, NEMA® 4X, and IP66/67

Burst Pressure11,000 psi (758.4 bar), 26,000 psi (1,792.6 bar) for scale ranges above 4,000 psi (275.8 bar)

Overpressure ProtectionUp to 150 times scale range

Max. Operating TemperatureAmbient: -40 to 185° F (-40 to 85° C)

Process: -40 to 250° F (-40 to 121° C)

Certifications/ApprovalsHazardous location, see full specs for complete list of certifications

AVENTICS™ Series PG1 Pressure gauges

With the AVENTICS Series PG1 you can visualize and rely on a clear air pressure display for each of your pneumatic circuits. In addition to the parameters for controlling the air quality, supplying sufficient pressure is the basis for operating a reliable system within machine automation. Emerson offers mechanical pressure gauges that can be integrated into machines for diverse applications and air preparation systems. The specifications of the individual versions in the universal PG1 Series provide a selection of options, such as appearance, material, or the required type of mounting.

Features

Clearly visible pressure indicators in different sizes and versions

Gauges available with or without adjustable work area display

Special gauges available like glycerine filled gauges or stainless-steel housing.

Subsea Pressure

Paine™ 220-30-020 Subsea Pressure and Temperature Transmitter

As a fully submersible device, the Paine™ 220-30-020 Subsea Pressure and Temperature Transmitter is a reliable solution for pressure and temperature measurement in remote subsea systems. This transmitter features digital measurement accuracy and utilizes the industry-standard CANopen® Digital Subsea Instrumentation Interface. With an all-welded design, this transmitter offers long-term subsea operation and meets the requirements of API 17F / ISO 13628-6 and CiA® 443 (SIIS level-2 device).

Specifications

Measurement Range0-15000 psia (0 to 1034 bar)

Operating Temperature25 °F to 140 °F (-4 °C to 60 °C)

Process MediaCompatible with 17-4 PH and 15-5 CRES

Pressure Port/Fitting220-30-020-01: 3/8 in. medium pressure female autoclave fitting 220-30-020-02: 3/8 in. high pressure female autoclave fitting

Paine™ 214-35-500 Pressure Transmitter

The Paine™ 214-35-500 Subsea Pressure Transmitter is a pressure measurement device engineered for remote subsea environments. For application flexibility, this transmitter is designed with a 3-wire or SEACON® subsea bulkhead connector options. This submersible transmitter is all-welded and highly corrosion resistant to withstand extreme depths, and is engineered with a rugged external enclosure to provide maintenance-free performance.

Specifications

Measurement Range0-1000 to 0-20000 psia (68 to 1378 bar)

Operating Temperature-65 to 230 °F (-53 °C to 110 °C)

Process MediaCompatible with 17-4 PH and 15-5 CRES

Pressure Port/Fitting1/4-18 NPT internal thread