↑ برای مشاهده محصولات بیشتر در این زمینه به کاتالوگ اصلی فوق مراجعه نمایید ↑

Electromagnetic Flowmeters

Electromagnetic flowmeters

Measuring for process management, revenue collection, liquid transportation and energy conservation. Whatever the application, ABB’s intelligent design, state-of-the-art technology and advanced features work harder and smarter to make your operations more efficient and cost effective.

ABB offers the most comprehensive range of EMF product lines tailored to your needs.

Electromagnetic flowmeter

ProcessMaster FEP630

Proven to be tough, reliable and incredibly easy to work with, ProcessMaster FEP630 delivers the power to solve your most demanding process applications.

This innovative, next generation electromagnetic flowmeter provides a modular transmitter design combined with SmartSensor technology and built-in verification – technical advances that deliver a clear business and performance benefit.

Ethernet IP communication increases operational performance and delivers more real-time data for a better decision making.

ProcessMaster FEP630 the perfect fit for your application and the no. 1 choice in sectors such as chemical, power, oil & gas, pulp & paper and metals & mining.

Detail

Measuring value error

– Standard 0.4 % of rate, option for 0.3% and 0.2 % of rate

Nominal diameter

– DN 3 to 2000 (1/10 to 80 in.)

Process connection

– Flange in accordance with DIN 2501 / EN 1092-1, ASME B16.5 / B16.47, JIS, AS2129

Nominal pressure

– PN 10 to 100,

– ASME CL 150, 300

Lining

– Hard rubber, soft rubber, PTFE, PFA, ETFE, Linatex

IP rating

– IP67 or IP68

Fluid temperature

– Up to 180 °C (356 °F)

Communication

– HART

– PROFIBUS DP, Profibus PA

– Modbus RTU, Modbus TCP

– Ethernet IP, Profinet

Webserver

Ex approvals

– ATEX, IECEx, cFMus, NEPSI

Process diagnostics

– Empty pipe, partially filling, gas bubbles, electrode impedance, conductivity, sensor temperature

ProcessMaster FEP610

ProcessMaster FEP610 offers robust, cost effective flow measurement with the industry´s widest range of liners, electrodes and sizes to meet the needs of all industrial standard applications.

The ProcessMaster´s concept comprises of uniform operating concept with a high degree of performance and reliability, assuring the longest service life.

Available as an integral or remote mount design – with or without local LCD display. All version use a common transmitter with easy to understand diagnostic messages for improved operator efficiency.

ProcessMaster FEP610 is ideally suited for all industrial standard applications.

Detail

Measuring value error

– 0.5 % of rate

Nominal diameter

– DN 3 to 2000 (1/10 to 80 in.)

Process connection

– Flange in accordance with DIN, ASME, JIS

Nominal pressure

– PN 10 to 40, ASME CL 150, 300, JIS 10K

Lining

– Hard rubber, soft rubber, PTFE, PFA, ETFE

HygienicMaster FEH630

Designed to meet highest levels of demands for enhanced metering in the Food & Beverage industry, HygienicMaster FEH630 delivers more than reliable and accurate measuring values.

This innovative next generation of electromagnetic flowmeters provides a modular transmitter design combined with SmartSensor technology and built-in verification – technical advances that deliver a clear business and performance benefit.

The sensor-design ensures optimum protection from breathing and condensation.

Exchangeable process connections for maximum flexibility, simplified installation and reduce inventory. The sensor is CIP/SIP cleanable, FDA approved and certified in accordance with 3A.

Ethernet IP communication increases operational performance and delivers more real-time data for a better decision making.

HygienicMaster FEH630 is one of the most cost saving flowmeters on the market and ideally suited for all hygienic applications.

Detail

Measuring value error

– 0.4 % of rate, Option for 0.3% or 0,2%

Nominal diameter

– DN 1 to 100 (1/25 to 4 in.)

Process connection

– Weld stubs, threaded pipe connections, Tri-clamps, wafer-type, flanges, external threads, flanges in accordance with DIN/EN, ASME, JIS

Nominal pressure

– PN 10 to 40, ASME CL 150, 300

Lining

– PFA vacuum stable

IP rating

– IP67 or IP68

Fluid temperature

– Up to 180 °C (356 °F)

Communication

– HART

– PROFIBUS DP, Profibus PA

– Modbus RTU, Modbus TCP

– Ethernet IP, Profinet

Webserver

Process diagnostics

– Empty pipe, gas bubbles, electrode impedance, conductivity, sensor temperature

Certificates

– 3A, FDA approved materials

HygienicMaster FEH610

HygienicMaster FEH610 is designed specifically for the food & beverage industries in a cost-effective, robust package.

The sensor is fully CIP/SIP cleanable, manufactured from FDA approved materials and certified with 3A.

Available as an integral or remote mount design – with or without local LCD display. All versions use a common transmitter with easy to understand diagnostic message for improved operator efficiency.

HygienicMaster FEH610´s variable process connections simplify installation and reduce inventory and replacement costs.

HygienicMaster FEH610 is ideally suited for hygienic standard applications.

Detail

Measuring value error

– 0.5 % of rate

Nominal diameter

– DN 1 to 100 (1/25 to 4 in.)

Process connection

– Weld stubs, threaded pipe connections, Tri-clamps, wafer-type, flanges, external threads, flanges in accordance with DIN/EN, ASME, JIS

Nominal pressure

– PN 10 to 40, ASME CL 150, 300

Lining

– PFA vacuum stable

Protection class

– IP 67 or IP 68

Fluid temperature

– Up to 130 °C (266 °F)

Certificates

– 3A, FDA approved materials

Coriolis Mass Flowmeters

Coriolis Mass Flowmeters

A wide range of meter sizes provide precise measurement of massflow, volume flow, density, temperature and concentration. ABB´s CoriolisMaster series has a history of success in a wide variety of industries and applications. With innovations like SensorApplicationMemory, Easy Set-up and with up to 5 modular I/Os – they save time and money during installation, commissioning and maintenance.

Benefits of using ABB´s CoriolisMaster flowmeters:

Save cost by making several measurements with one device

Reduce flowmeter maintenance by up to 90 %

No mechanical wear and minimize installation issues

Save up to 25 % on pump power

Save critical installation space

CoriolisMaster FCB400

CoriolisMaster FCB400 series of compact Coriolis mass flowmeters feature low pressure drop, high capacity, intuitive ABB common display, five modular I/O`s and various communication protocols, now with OIML R117 and MID approved.

General specifications:

Nominal sizes / measuring ranges

– DN 15 (1/2 in.) / 0 to 8,000 kg/h (17,637 lb/h)

– DN 25 (1 in.) / 0 to 35,000 kg/h (77,162 lb/h)

– DN 50 (2 in.) / 0 to 90,000 kg/h (198,416 lb/h)

– DN 80 (3 in.) / 0 to 250,000 kg/h (551,156 lb/h)

– DN 100 (4 in.) / 0 to 520,000 kg/h (1,146,404 lb/h)

– DN 150 (6 in.) / 0 to 860,000 kg/h (1,895,975 lb/h)

Ex approvals

– ATEX zone 0/1/2, cFMus Div 1/2 and zone 0/1/2

– NEPSI Zone 0/1/2

– Various other approvals

– OIML R117; MID approved

Wetted materials

– 1.4404 / 1.4435 (316L) or Hasteloy C

Accuracy for liquids

FCB430

– Mass and volume: 0.4 % o. r. / 0.25 % o. r. / 0.2 % o. r.

– Density: 10 g/l

FCB450

– Mass: 0.15 % o. r. / 0.1 % o. r., volume: 0.15 % o. r.

– Density: 0.002kg/m3 or 0.001kg/m

Measuring medium temperature

FCB430

– -50 to 160 °C (-58 to 320 °F)

FCB450

– -50 to 205 °C (-58 to 400 °F)

Outputs

– 5 modular I/Os

– HART 7.1

– PROFIBUS DP

– Modbus

– Ethernet

Ethernet IP

Modbus TCP

Webserver

More protocols in preparation

Power supply

– 11 to 30 V DC, 110/230 V AC

– Power over Ethernet

CoriolisMaster FCH430 and FCH450

CoriolisMaster FCH400 series of compact Coriolis mass flowmeters for hygienic applications feature low pressure drop, high capacity, intuitive ABB common display, five modular I/Os and various communication protocols.

The FCH400 series offers on top EHEDG certified cleanability with polished wetted materials.

General specifications:

Nominal sizes / measuring ranges

– DN 25 (1 in.) / 0 to 35,000 kg/h (77,162 lb/h)

– DN 50 (2 in.) / 0 to 90,000 kg/h (198,416 lb/h)

– DN 80 (3 in.) / 0 to 250,000 kg/h (551,156 lb/h)

Ex approvals

– ATEX zone 0/1/2, cFMus Div 1/2 and zone 0/1/2

– NEPSI Zone 0/1/2

– Various other approvals

Hygienic approvals

– EHEDG and FDA material compliant

Wetted materials

– 1.4404 / 1.4435 (316L)

Accuracy for liquids

FCH430

– Mass and volume: 0.4 % o. r. / 0.25 % o. r. / 0.2 % o. r.

– Density: 10 g/l

FCH450

– Mass: 0.15 % o. r. / 0.1 % o. r., volume: 0.15 % o. r.

– Density: 2 g/l or 1 g/l

Measuring medium temperature

FCH430

– -50 to 160 °C (-58 to 320 °F)

FCH450

– -50 to 205 °C (-58 to 400 °F)

Outputs

– 5 modular I/Os

– HART 7.1

– PROFIBUS DP

– Modbus

– Ethernet

Ethernet IP

Modbus TCP

Webserver

More protocols in preparation

Power supply

– 11 to 30 V DC, 110/230 V AC

– Power over Ethernet

CoriolisMaster FCB130 and FCB150

CoriolisMaster FCB100 series of compact system integration flowmeters feature low pressure drop, high flow capacity, high speed RS485 Modbus communication and 2 digital outputs.

General specifications:

Nominal sizes / measuring ranges

– DN 15 (1/2 in.) / 0 to 8,000 kg/h (17,637 lb/h)

– DN 25 (1 in.) / 0 to 35,000 kg/h (77,162 lb/h)

– DN 50 (2 in.) / 0 to 90,000 kg/h (198,416 lb/h)

– DN 80 (3 in.) / 0 to 250,000 kg/h (551,156 lb/h)

– DN 100 (4 in.) / 0 to 520,000 kg/h (1,146,404 lb/h)

– DN 150 (6 in.) / 0 to 860,000 kg/h (1,895,975 lb/h)

Ex approvals

– ATEX zone 0/1/2, cFMus Div 1/2 and zone 0/1/2

Wetted materials

– 1.4404 / 1.4435 (316L) or Hasteloy C

Accuracy for liquids

FCB130

– Mass and volume: 0.4 % o. r. / 0.25 % o. r.

– Density: 10 g/l

FCB150

– Mass: 0.15 % o. r. / 0.1 % o. r., volume: 0.15 % o. r.

– Density: 2 g/l or 1 g/l

Measuring medium temperature

FCB130

– -50 to 160 °C (-58 to 320 °F)

FCB150

– -50 to 205 °C (-58 to 400 °F)

Outputs

– 2 digital out (pulse, frequency, contact)

– Modbus

Power supply

– 11 to 30 V DC

CoriolisMaster FCH130 and FCH150

CoriolisMaster FCH100 series of compact hygienic system integration flowmeters feature low pressure drop, high flow capacity, high speed RS485 Modbus communication and 2 digital outputs.

The FCH100 series offers on top EHEDG certified cleanability with polished wetted materials.

General specifications:

Nominal sizes / measuring ranges

– DN 15 (1/2 in.) / 0 to 8,000 kg/h (17,637 lb/h)

– DN 25 (1 in.) / 0 to 35,000 kg/h (77,162 lb/h)

– DN 50 (2 in.) / 0 to 90,000 kg/h (198,416 lb/h)

– DN 80 (3 in.) / 0 to 250,000 kg/h (551,156 lb/h)

– DN 100 (4 in.) / 0 to 520,000 kg/h (1,146,404 lb/h)

– DN 150 (6 in.) / 0 to 860,000 kg/h (1,895,975 lb/h)

Ex approvals

– ATEX zone 0/1/2, cFMus Div 1/2 and zone 0/1/2

Wetted materials

– 1.4404 / 1.4435 (316L) or Hasteloy C

Accuracy for liquids

FCB130

– Mass and volume: 0.4 % o. r. / 0.25 % o. r.

– Density: 10 g/l

FCB150

– Mass: 0.15 % o. r. / 0.1 % o. r., volume: 0.15 % o. r.

– Density: 2 g/l or 1 g/l

Measuring medium temperature

FCB130

– -50 to 160 °C (-58 to 320 °F)

FCB150

– -50 to 205 °C (-58 to 400 °F)

Outputs

– 2 digital out (pulse, frequency, contact)

– Modbus

Power supply

– 11 to 30 V DC

Differential Pressure Flowmeters

Differential pressure flowmeters

From simple orifice plates through to custom-engineered metering systems, ABB’s differential pressure (DP) flowmeters measure a variety of fluids including water, air, steam, heavy oil, slurries and molten sulfur.

Orifice plates

ABB orifice plates are available for both flow measurement and flow restriction services. Designs are available for mounting directly between RF or RTJ flanges, and there is an option to include weld-neck orifice flanges. They offer an economic solution to flow measurement/restriction applications.

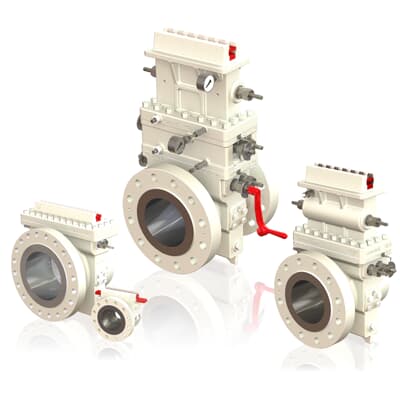

Orifice assemblies

ABB orifice assemblies cover applications where a simple plate is not suitable. They comprise an orifice plate mounted in a carrier assembly or metering run. The range includes specialised fiscal orifice assembles for the Oil & Gas industry, which offer single- and dual-chamber units, as well as a dual chamber unit with DBB (double block and bleed) isolation.

Wedge elements

ABB’s FPD470 Wedgemeter family measures liquids, gas and steam. They have a solid V-shaped flow restriction which makes them extremely robust. FPD470 wedge meters are bi-directional and particularly suitable for abrasive and / or viscous fluids / slurries.

Compact DP flowmeters

ABB’s Compact DP flow meters are all 1-piece assemblies that come fully factory-configured and pressure tested, solving many of the problems associated with sizing, selection, installation and operation of conventional DP flow systems. They combine all the major components needed into single assemblies, saving time and cost in the engineering and procurement processes, as well as eliminating the need for users to specify, source and install many separate components.

Orifice Plates

Orifice plates for flow FPD150

Flow measurement plates to fit between RF, FF or RTJ flanges

Available as Concentric (square edged, conical entrance and quarter circle profile) or Eccentric (eccentric and segmental profile) designs to measure the flow of clean or contaminated liquids, gases or steam.

Data

Orifice Plate designs:

– Concentric Square Edge Orifice Plate for clean liquids/gases/steam

– Quarter Circle Orifice Plate for viscous fluids

– Conical Entrance Orifice Plate for viscous fluids

– Eccentric Orifice Plate for dirty fluids

– Segmental Orifice Plate for dirty fluids

– Orifice Plate in holder to fit between RTJ pipe flanges

Orifice flange assemblies FPD160

Weld-in Orifice Flange Unions/Assemblies to fit between RF, FF or RTJ flanges.

Orifice flanges include the DP tapping points and are supplied with the necessary orifice plate, gaskets, nuts, bolts and jacking screws, designed to measure the flow of clean or contaminated liquids, gases or steam.

Detail

Accuracy

Uncertainty at design flow:

Typically 0.5% … 1.2%

Media Steam, liquids, gas

Operating conditions

Pressure: up to PN100

Temperature: acc. EN1092-1 / ASME B16.5

Installation conditions

Inlet: depends on β-coefficient (typically 16 … 44 x inner diameter)

Outlet: depends on β-coefficient (typically 6 … 8 x inner diameter)

Design

Acc. to ISO 5167 (2003)

Acc. to PED 2014/68 EU

Approvals

Ex, SIL, … acc. SITRANS P320

Restriction orifice plates FPD190

The FPD190 restriction orifice plates are used where there is a requirement either to reduce the line pressure or alternatively to restrict the flowrate to a certain value.

Data

Product designs:

– restriction orifice plate

– multi restriction orifice spool

Orifice Assemblies

Integral orifice flow element 1330L

The integral orifice is a flow element can be close -coupled with differential pressure transmitters to make a complete flow meter. It provides easy-to-install, low-cost measurement of the small flows found frequently in plant metering operations and research projects.

Data

Key features:

– 1/2, 1 and 11/2 in. NPT sizes

– ±0.5% accuracy when calibrated

– Flanged construction

– Wide variety of standard bores

Orifice carrier assemblies OCA

A more convenient alternative to simple orifice plates is an assembly comprising an orifice plate mounted in a carrier that already has the correct tapping points fitted. ABB has a wide range of these carrier assemblies for different applications.

Data

The integral orifice carrier assembly is a one-piece orifice plate and carrier ring with integral corner differential pressure tappings and is designed to fit between raised-face flanges.

The split ring orifice carrier assembly is a dual-ring orifice carrier with differential pressure tappings and is designed to fit between raised face flanges. The carrier rings incorporate corner or flange taps.

Orifice meter run OMR

When high accuracy flow measurement of liquids, gases and steam is demanded from the primary flow element, an orifice flange assembly can be welded into a fabricated orifice meter run, incorporating the upstream and downstream pipe sections required by ISO5167-1:2003.

Data

Flowmeter designs:

– FMR (Fabricated Orifice Meter Run)

– IMR (Integral Orifice Meter Run) incorporating kidney flange impulse connections

Orifice carrier assembly with integral manifold FPD175

A more convenient alternative to simple orifice plates is an assembly comprising an orifice plate mounted in a carrier that already has the correct tapping points fitted. ABB has a wide range of these carrier assemblies for different applications.

Data

Enhanced flexibility for the user

– create a one-piece flowmeter by direct-mounting a DP or Multivariable transmitter

– or mount transmitter remotely for applications where direct-mounting is not practicable or not required

Low cost maintenance

– Optional removable orifice plates for on site, low cost solutions to changes in process data or element wear/damage

Accurate installation in the pipeline, every time

– Centralising tool supplied as standard, ensuring accurate centralisation of meter in the pipeline

Wedge Elements

Wedge meter flow element

FPD470C

FPD470C wedge meters have DP connections for Chemical Tee remote seals. The flow element consists of a body and wedge flow restriction. This restriction creates a differential pressure in proportion to the square of the volumetric flow rate.

Data

Measures liquids, gas and steam

High Accuracy ±0.5 % of rate

Bi-directional flow

Low Reynolds number measurement (as low as Rd 500)

Minimum upstream and downstream piping requirements

Standard sizes 0.5 to 24 inch

Wedge meter flow element

FPD470F

The FPD470F is a wedge meter with DP connections for flanged remote seals. The flow element consists of a body and wedge flow restriction. This restriction creates a differential pressure in proportion to the square of the volumetric flow rate.

Data

Measures liquids, gas and steam

High Accuracy ±0.5 % of rate

Bi-directional flow

Low Reynolds number measurement (as low as Rd 500)

Minimum upstream and downstream piping requirements

Standard sizes 1.5 to 24 inch

Wedge meter flow element

FPD470P

The FPD470P is a wedge meter with threaded DP connections for connection to conventional transmitters . The flow element consists of a body and wedge flow restriction. This restriction creates a differential pressure in proportion to the square of the volumetric flow rate.

Data

Measures liquids, gas and steam

High Accuracy ±0.5 % of rate

Bi-directional flow

Low Reynolds number measurement (as low as Rd 500)

Minimum upstream and downstream piping requirements

Standard sizes 1 to 24 inch

Compact DP Flowmeters

Compact orifice flowmeter

OriMaster FPD500

OriMaster is a compact orifice flowmeter that combines a wafer-mounted orifice carrier, integral manifold and transmitter into a single, fully-codable, orifice-based flowmeter.

Data

One-stop source for the complete orifice meter package

– Purchase all the components from one supplier using a single ordering code, saving $$ in procurement and order-progressing activities. Ensures application suitability for the DP transmitter and the primary DP device.

Enhanced reliability, reduced maintenance

– As a one-piece flowmeter, pressure tested at the factory, problems during commissioning and operation associated with impulse line leakage – as well as installation errors – are virtually eliminated.

Low cost maintenance

– Pressure-tested in the factory for leak prevention

– Removable orifice plates for on site, low cost solutions to changes in process data or element wear/damage

Compact integral orifice flowmeter

IOMaster FPD510

A fully coded, one-piece flowmeter that combines the features and benefits of integral orifice metering with a 3- or 5- valve instrument manifold and the latest ABB DP and multivariable transmitters.

Data

Utilizes ABB’s new 266 series DP and multivariable transmitters with optional Through The Glass technology

– enables meter configuration without the removal of the transmitter cover

Option of alloy or stainless steel transmitter body

– enables supply of an all-stainless-steel, one piece flow meter

– for ambient conditions require stainless steel exposed parts

Integral ABB 266CSH multivariable transmitter available

– measures DP, Pressure and Temperature

– enables flowmeter to measure mass or corrected gas volume

Available in small pipe sizes

– pipe sizes of DN15, DN25 or DN40 (½, 1 or 1½ in.)

– for small flowrates and pilot plant applications

Replaceable orifice plates as standard for all sizes

– enables easy modification to changes in process conditions / fluid

Option of female-threaded or welded flanged pipework connections

– range of process connections to suit installation

Compact averaging pitot flowmeter

PitoMaster FPD550

PitoMaster is a Compact Averaging Pitot Flowmeter that combines a threaded or flanged-mounted insertion meter,an integral 3- or 5-valve manifold and a transmitter into a single, fully-codable insertion flowmeter.

Data

Low operating costs with small carbon footprint

– PitoMaster’s low profile design creates minimal pressure losses, giving genuine savings in pumping/compression costs, with consequent reductions in energy usage and hence in CO2 emissions.

Economical metering in larger pipe sizes

– Low rate of cost increase with increasing pipe size provides metering at a low purchase cost for larger pipe sizes.

Large flow turndown means increased usability

– Unique profiled flats on probe define flow separation point, giving more constant flow coefficient at high velocities and a wide range of flow measurement (turndown).

Low cost, easy installation into existing pipelines

– Simple one- or two hole installation with mounting adapters supplied.

– No need to cut pipe and weld in flanges.

Compact wedge meter

WedgeMaster FPD570

WedgeMaster compact wedge flow meters, offer a focus on providing solution-solving flowmeter systems, coupled to the latest in ABB transmitter technology.

Data

One-stop source for the complete Wedge meter package

– Purchase all the components from one supplier using a single ordering code, saving cost in procurement and order-progressing activities.

Reduced cost and space for process piping

– Requires as little as 5D upstream and 2D downstream of straight pipe, saving on expensive provision of pipework and space.

Excellent turndown and long term stability

– no critical surface dimensions to wear; durable design and construction

– maintains flow characteristics down to Re 500, offering wide flow turndown, even with more-viscous fluids.

Easy, low cost, accurate installation

– Reduces installation cost by up to 50% compared to a traditional DP system.

– Assembly, leak testing and basic configuration has already been done before shipment .

Thermal Mass Flowmeters

Thermal mass flowmeters

ABB’s thermal mass flowmeters are suitable for all industrial and test rig applications that demand quick and precise gas measurement. The flowmeters directly indicate the mass flow or normalized volume flow of gases without any additional pressure and temperature compensation. They have an impressively high accuracy, short response time and a very wide flow range with virtually no loss of accuracy even at the lowest flow rates.

Thermal mass flowmeter

SensyMaster FMT200

The SensyMaster FMT230 offers a high quality and cost effective solution for precise and dynamic direct mass flow measurements of gases in low and medium pressure conditions. The model comes preconfigured for the application, ready to be installed by OEM customers.

The FMT250 adds high accuracy and extended functionality for advanced applications.

SensyMaster’s concept comprises high grade thermal sensor elements with superior long-term stability, the ABB platform based electronics with comprehensive signal evaluation capabilities for a high degree of performance and reliability. The software offers the ApplicationSelector that allows to change application parameters and create new applications on site and VeriMass the fingerprint based thermal sensor element verification function.

Both models communicate via MODBUS Interface and follow the SmartSensor concept.

The SensyMaster FMT230 is ideally suited for all OEM applications, the FMT250 for advanced OEM application.

General specifications:

Measuring media

– Air, Nitrogen, Oxygen, Carbon dioxide, Methane, Hydrogen, Natural Gas, Biogas, Helium, Argon, Propane, Ethane, Ethene, Butane, Ammonia, more gas types on request

FMT230 measuring accuracy for air under reference conditions

– ±1.2 % of rate within 10 … 100 % of measuring range

– ±0.12 % full scale within 1 … 10 % of the measuring range

FMT250 measuring accuracy for air under reference conditions

– ±0.6 % of rate ±0.05 % full scale

FMT250 measuring accuracy for gases under reference conditions

– with optional process gas calibration

– ±1.6 % of rate ±0.1 % full scale

Integral mount transmitter design

– single compartment transmitter housing

Measuring medium temperature

– -25 … 150 °C (-13 … 302 °F)

Ambient temperature

– -20 … 70°C ( -4 … 158°F)

– optional -40 … 70 °C (-40 … 158 °F)

– optional -50 … 70 °C (-58 … 158 °F)

Supply Voltage

– 24 V DC ±20 %

Process adaption via pipe components in different designs

– partial measuring sections (DN 25 …DN 100)

– wafer design pipe components (DN 40 … DN 200)

– Weld-on adapters (DN 100 … DN 3000)

FMT250 added functionality

– high accuracy calibration

– process gas calibration

– extended Measuring range

– high medium temperature up to 300 °C (572 °F)

– filling application software

– ApplicationSelector with up to 8 applications

…with up to 4 customer set applications

…with selectable gas type

…with selectable pipe inner diameter

Thermal mass flowmeter

SensyMaster FMT400

The SensyMaster FMT430 offers a high quality and cost effective solution for precise and dynamic direct mass flow measurements of gases in low and medium pressure conditions to meet the needs of all industrial standard applications.

The FMT450 adds high accuracy and extended functionality for advanced industrial applications.

SensyMaster’s concept comprises high grade thermal sensor elements with superior long-term stability, the common ABB look and feel with ABB specific menu structures and through-the-glass-operation and the ABB platform based electronics with comprehensive signal evaluation capabilities for a high degree of performance and reliability. The software offers the ApplicationSelector that allows to change application parameters and create new applications on site and VeriMass the fingerprint based thermal sensor element verification function.

Both integral and remote mount design is available with or without local display and HART communication supporting the modular I/O and the SmartSensor concept. Both models offer easy to understand diagnostic messages for improved operator efficiency.

The SensyMaster FMT430 is ideally suited for all industrial standard applications, the FMT450 for advanced industrial application.

General specifications:

Measuring media

– Air, Nitrogen, Oxygen, Carbon dioxide, Methane, Hydrogen, Natural Gas, Biogas, Helium, Argon, Propane, Ethane, Ethene, Butane, Ammonia, more gas types on request

FMT430 measuring accuracy for air under reference conditions

– ±1.2 % of rate within 10 … 100 % of measuring range

– ±0.12 % full scale within 1 … 10 % of the measuring range

FMT450 measuring accuracy for air under reference conditions

– ±0.6 % of rate ±0.05 % full scale

FMT450 measuring accuracy for gases under reference conditions

– with optional process gas calibration

– ±1.6 % of rate ±0.1 % full scale

Integral and remote mount transmitter design

– single and dual compartment transmitter housing options

Measuring medium temperature

– -25 … 150 °C (-13 … 302 °F)

Ambient temperature

– -20 … 70°C ( -4 … 158°F)

– optional -40 … 70 °C (-40 … 158 °F)

– optional -50 … 70 °C (-58 … 158 °F)

Supply Voltage

– 100 … 240 V AC (-15 / +10 %)

– 24 V DC ±20 %

Process adaption via pipe components in different designs

– partial measuring sections (DN 25 …DN 100)

– wafer design pipe components (DN 40 … DN 200)

– Weld-on adapters (DN 100 … DN 3000)

FMT450 added functionality

– high accuracy calibration

– process gas calibration

– extended Measuring range

– high medium temperature up to 300 °C (572 °F)

– filling application software

– ApplicationSelector with up to 8 applications

…with up to 4 customer set applications

…with selectable gas type

…with selectable pipe inner diameter

Thermal mass flowmeter

Sensyflow FMT200-ECO2

Sensyflow FMT200-ECO2 is a very compact and highly dynamic mass flowmeter for air. It offers a direct mass or standard volume flow measurement in pneumatic applications, e. g. in paint robot control or compressed air systems.

Data

Variable process adapters

– tubes, threads, ISO-KF flanges DN 25

Adjustable output signals

Measuring range 1 to 100 kg / h (12 to 1250 l / min)

Serial port RS 232

ATEX version for zone 2 and 22

Thermal mass flowmeter

Sensyflow FMT700-P and FMT700-P Compact

Sensyflow FMT700-P is for direct mass flow measurement of air. The measurement is independent of operating pressure and temperature. It supplies best accuracy together with an unrivalled response time. Used in quality assurance, test bench applications, research and development.

It is the reference system for intake air measurement of the leading car manufacturers worldwide.

Data

Direct mass flow measurement of air

– No additional pressure and temperature compensation required

High measuring accuracy over the entire measuring range

– Measuring accuracy up to < 0.8 % of measured value

Wide measuring range of up to 1:60

– Measurement up to 5000 kg/h

– DN 25 to DN 200

Quick response time < 25 ms

– Detection of rapid load changes on engine test benches

Complete system with inlet / outlet sections, flow conditioner and connection parts

– Easy to use

– Ready for operation

Used in test bench applications, quality assurance, research and development

Variable Area Flowmeters

Variable area flowmeters

Variable area flowmeters are the most cost effective solution for almost all applications involving the measurement of industrial process liquids, gases or steam. ABB´s variable area flowmeters are reliable, flexible and simple. They meet the application requirements by featuring a wide range of design varieties and sizes. Technology proven, they offer a long life and high reproducibility. Variable area flowmeters are excellent mechanical back-up meters because no external power supply is needed.

Armored variable area purgemeter

FAM3200

The FAM3200 is an armored purgemeter designed to meter small gas and liquid flows. This meter is especially suited for applications with cloudy, opaque or aggressive fluids in chemical and pharmaceutical industries, gas analyzers, process systems, well systems and wherever glass metering tubes cannot be used for safety reasons.

General specifications:

Application

– Clean, low viscosity liquids and gases

Mounting

– Vertically, in line or wall mouted

Connections

– 1/4 to 1 in., threaded, vertical or horizontal

Flow ranges

– Water flows: 1 to 3000 l/h

Flow turndown

– Typically 10:1

Operating pressure

– Up to 100 bar (1450 lbf/in 2 g)

Operating temperature

– Up to 180 °C (356 °F)

Accuracy

– Class 6

Alarms

– Slot sensors, up to 2 off

Tube material and float material

– Stainless steel

Metal cone variable area flowmeter

VA Master FAM540

The VA Master FAM540 flowmeter can be utilized for measuring the flow of liquids, steam and gases, especially when aggressive or opaque fluids are to be metered.

It is ideal for the chemical, pharmaceutical and food and beverage industries.

General specifications:

Application

– Clean liquids, gases and steams

Mounting

– Vertically, in line

Connections

– 1/2 to 4 in., flanged, hygienic (DIN, SMS), vertical

Flow ranges

– Water flows: 0.028 to 120 m3/h

Flow turndown

– Typically 10:1

Operating pressure

– Up to 100 bar (1450 lbf/in 2 g)

Operating temperature

– Up to 400 °C (752 °F)

Accuracy

– Class 1.6 (Class 2.5: PTFE line tubed opt.)

Alarms

– Slot sensors, up to 2 off

Tube material

– Stainless steel, optional PTFE lined

Float material

– Stainless steel, optional PTFE lined/float damping

Vortex Flowmeters

Vortex flowmeters

The robust design of ABB’s vortex flowmeters provides high performance and reliability in liquid, gas and steam measurements. Equipped with digital signal processing (DSP) and advanced filtering techniques, these innovative flowmeters from ABB allow excellent flow signal detection and provide measurement immunity from the effects of hydraulic noise and pipeline vibration.

VortexMaster FSV430

VortexMaster FSV430 is the basic meter for volume flow applications. Available in flange-mount and wafer-type designs, VortexMaster FSV430 uses a two-wire transmitter with leading edge DSP-technology with excellent vibration compensation. Intuitive operation directly through the glass makes the FSV430 incredibly user-friendly.

General specifications:

Intuitive operation

– Easy Set-up function

– Clear text display

– Meter configuration through the front glass with closed cover

Accuracy for liquids

– +/- 0.65% of rate

Accuracy for gases and steam

– +/- 0.9% of rate

Process connection / meter sizes

– Flange-mount design / DN 15 to 300 (1/2 to 12 in.)

– Wafer type design / DN 25 to 150 (1 to 6 in.)

Approvals for explosion protection

– ATEX, IECEx, cFMus, NEPSI

SIL2-certified in accordance with IEC 61508

Output / communication

– 4 to 20 mA / HART 7

– Modbus RTU-RS485

Optional binary output

– For use as a limit switch, pulse output or frequency output

Optional input from field

– Pressure, temperature, methane content, density gas analyzer

VortexMaster FSV450

VortexMaster FSV450 is the universal vortex meter for high end flow applications. It uses a two-wire transmitter with leading edge DSP-technology with enhanced flow computer functionality. Signals from remote sensors like pressure, temperature, density or gas content can be read in by an integrated analog 4 … 20 mA interface and computed directly with the flow and temperature signals measured by the device itself. FSV450 is ideal for direct mass flow or standard flow of gasses and liquids or direct mass and energy flow on saturated and overheated steam.

General specifications:

Intuitive operation

– Easy Set-up function

– Clear text display

– Meter configuration through the front glass with closed cover

Accuracy for liquids

– +/- 0.65% of rate

Accuracy for gases and steam

– +/- 0.9% of rate

Process connection / meter sizes

– Flange-mount design / DN 15 to 300 (1/2 to 12 in.)

– Wafer type design / DN 25 to 150 (1 to 6 in.)

Approvals for explosion protection

– ATEX, IECEx, cFMus, NEPSI

SIL2-certified in accordance with IEC 61508

Output / communication

– 4 to 20 mA / HART 7

Optional binary output

– For use as a limit switch, pulse output or frequency output

Optional input from field

– Pressure, temperature, methane content, density gas analyzer

Integrated flow measurement computer functionality

– Gas standard volume and mass flow

– Vapor mass flow

– Direct energy calculation for vapor and water

– Natural gas calculation in accordance with AGA /SGERG standards